Sawmills & Planermills

Redwood Plastics and Rubber was the first in bringing wear solutions to the forestry industry. Solutions such as wear strip, kiln cart bushings and impact pads are just some of the products that paved the way for the hundreds of products that are used today. Redco™ plastics and rubber products have been proven to decrease downtime, and reduce noise, vibration and power consumption. Increase production to its fullest potential by adding Redco™ plastic and rubber products; bringing benefits and savings to your site. Redwood Plastics and Rubber specializes in a variety of applications including; shaft bearings, chip screens, channel, sheaves and conveyor liners. Replacing traditional materials with Redco™ plastics and rubber products has never been so easy with the varieties now available.

Cut costs, reduce wear and increase productivity.

APPLICATIONS:

Channel & channel inserts, bearings, bearing blocks, chipper spouts, conveyor flights, diverter arms, drop grate arms, hooks, rollers, metal detector troughs, oregon bends, saw blade carriers and covers, slider blocks, sound dampening cushions, tipple gates, trimmer lugs, wear plate, wearstrip, etc.

PRODUCTS:

- Redco™ Chain Channel

- Redco™ Bushings and Bearings

- Redco™ Sprockets

- Redco™ Sheaves and Pulleys

- Redco™ FRP Grating

- Redco™ Plastic Liners

- Redco™ Rubber Liners

- Redco™ Rubber Rollers and Roller Recoats

- Redco™ Flexible PVC/Strip Door

REDCO™ FEATURE APPLICATIONS:

Redco™ High Performance Materials

If your plastic parts are wearing too quickly it may be due to an improper material selection or you may need to upgrade the type of material that is being used. Redco™ Deadplate, Redco™ PVM, Redco™ SL & SXL, as well as Redco™ Titanium were all engineered to last much longer than mainstream industrial plastics.

Download the PDF for more information.

Redco™ Chain Channel Inserts

Less wear on your chain, less noise and less maintenance costs without having to change out your metal channel. These inserts simply fit into your current channel. Available in C3 and C4 profiles and compatible with 81x, 81xH, 2060, 2080 and H78 chain. UHMW wearing out too quickly? Ask about Redco™ Titanium.

Redco™ Snap It Sprocket requires no bolts and is easy and quick to assemble; simply match the arrows on the a-plate and snap together.

- Reduce Maintenance Costs

- Snap It is Easy to Install

- PDF Brochure – Snap It Sprocket

- Watch – Installation Video

Click here for more information on Redco Sprockets.

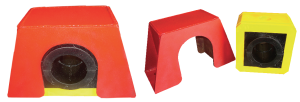

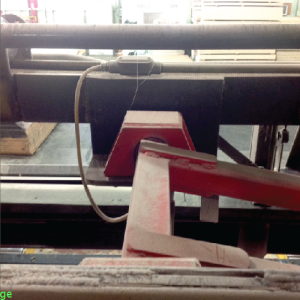

Replacing knives on a chip n’ saw shaft or chipping canter can be a difficult and time consuming job. Rotating the shaft to replace the extremely sharp blades that cut through gloves and hands can make it a dangerous job as well. The Redco™ CNS Knife Tool, SwitchSafe™, saves you time and saves your hands from injury. Download PDF.

SAFETY FIRST™

Switch out chip n’ saw knives quickly and easily without injury.

Tool Features:

- High impact strength

- Durable

- Lightweight

Available in a variety of grades including Redco™ UHMW, Redco™ Nylon, Redco™ Polyurethane, and Redco™ PTFE.

Download PDF for standard styles available. Custom sizes available.

Redco™ Flange Cap

• Standard Color: Yellow

• Fits W8 x 10 Wide Flange

• Planermill Unscrambler

• Planermill Sorter Bin Walls

• Sawmill Sorter Bin Knees

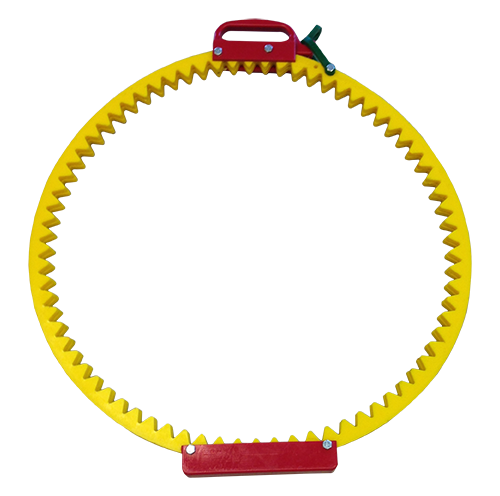

Redco™ Circular Saw Blades

Constructed of highly durable, cut resistant Redco™ Urethane our saw blade carriers also prevent any damage to the blade teeth during blade changes which reduces maintenance and replacement costs.

Redco™ Circular Saw Blade Carriers are designed with a flat bottom to enable the blade and carrier to stand upright when placed on the ground. They are also fitted with a steel pin latch to ensure the carrier stays closed during transport.

• Steel pin latch

• Kraft pulp friendly

• Ergonomically correct

• Flex fit

• Increases safety

Available Sizes: 16”, 18”, 20”, 22”, 24” & 26” (maximum) – Custom sizes available.

Standard Color: Safety Yellow

Download PDF Brochure

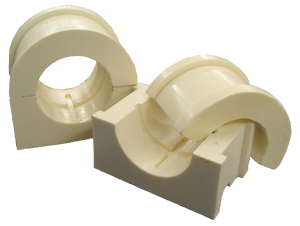

Redco™ 750 SN/SAF Bearing Inserts

- Split for quick and easy installation

- Save down time expenses

- Long life and durability

- Custom sizes available

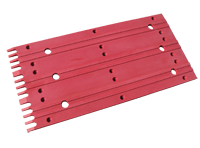

Redco™ Synsteel Chip Screens

- Faster flow over screen

- Less problems with pitch build-up and freeze up

- Longer wear – up t 100% longer wear

- Fewer hang ups

Top Screens: Usually done in 2 or 3 sections depending on the sizes: should be supported. 18-24″ to allow for sag – if possible, 16″ centers would be ideal.

Fine Screens: Usually done in the same manner only with smaller holes – 3/8″ dia. & larger, some 5/16″. Counter sinking the back of the holes prevents material from lodging within the holes.

Redco™ UHMW Wearplate

Used extensively to reduce wear, eliminate noise and cut installation cost, UHMW polyethylene is a proven alternative to AR plate. Available in full sheets, cut to size strips or the various profile shapes. It is easy to install using the plugweld fastening system. Download UHMW Strip Fastening Recommendations.

- Ask us about 250′ coils of wearstrip.

- Stock thicknesses are 1/8″ through 3/4″, increasing in 1/8″ increments, 3/4″ through 4″ thick increasing by 1/4″.

- Wearstrip is offered in standard 10 foot lengths and may be ordered by advising thickness, width and total length.

- Standard sheet sizes are 4′ x 10′ with 5′ x 10′ and 5′ x 12′ available on request.

Large logs can be hard on equipment. Redco Dissipater Channel absorbs the shock to prolong equipment life and reduce noise. Download PDF Brochure

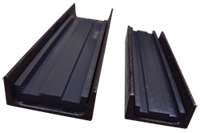

Redco UHMW chain channel reduces noise and friction as well as extends the life of your chain. Chain guides are available in a variety of profiles and grades including kraft pulp mill safe; Redco Synsteel as well as high temperature, anti-static and Redco Tivar.

Download PDF Chain Channel Profile Drawings

Redco™ Nylon & Tivar88 Chain Bed for Sharp Chain

Redco Nylon or Tivar 88 Chain Beds reduce chain lubricant requirements by nearly 75%; lowering maintenance costs and increasing the life of the chain.

- The chain bed is machined to precision, insuring the chain will be guided with accuracy.

- Available in either Redco Nylon SL or Tivar 88.

- Lightweight for easy replacement by a single maintenance person.

- Adapts to any existing machine using sharp chains from single strand to a multiple strand chain.

Redco™ PVM Sharp Chain Beds

A premium material that lasts much longer than standard UHMW.

Drastically reduces change-out frequency, extends the life of your chain, and reduces maintenance time.

Redco™ UHMW Conveyor Flights

- 50% the weight of cast steel

- Reduces noise

- Reduces power consumption

- Low coefficient of friction

- Easy to replace worn or damaged sections

- Easy to install

- Eliminates wear on conveyors

• Available in 4″ & 5″ Heights

• Sizes 16″ – 36″

• Bolted to Standard Long Link Chains

• Extra strength due to 1″ steel support bar or lighter with 1 1/2″ x 3 structural steel tubing

Redco™ Trimmer Lugs

Redco roller lug assemblies are excellent for moving boards on double end trimmer set ups. The roller sits on a steel pin and turns freely.

- Base of Pin: 1 1/2″ Diameter

- Pin Shaft: 1″ Diameter

- Part includes PIN, ROLLER, and WELD WASHER for installation of top of roller.

Redco™ Oregon Bends

- Low coefficient of friction for smooth chain flow

- Easy installation

- Protects chain from metal-to-metal wear

- Custom made configurations are available.

Redco™ 9600 Split Impact Bearings

The Redco™ 9600 Bearing is designed specifically for heavy duty, high impact applications. The unit consists of a tough, abrasion resistant urethane bearing (Redco™ 750 or 750XL), surrounded by a softer, more resilient shock absorbing urethane (Redco™ 70A – 1 15/16 & 2 13/16”) (Redco™ 430 – all over sizes), and then encased in a durable fabricated steel housing.

This unique design allows the bearing to withstand continuous shock loads while greatly reducing fatigue to the bearing housing and structural welds and mill supports. Download the PDF for more information.