Food & Beverage

aandExtreme temperatures, sanitation and contamination can cause frustrating problems in food processing environments. Redwood Plastics products can resolve many of these frustrations with materials that are non-conductive, chemical resistant, FDA/USDA/3A Dairy compliant, and impervious to hot and cold temperatures. Redco™ Plastic Products are the perfect solution for parts that are wearing out prematurely due to rust or chemical wash-downs.

APPLICATIONS:

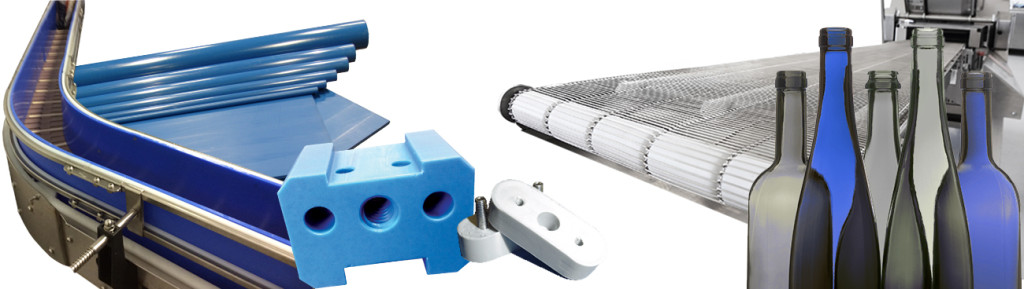

Bearings, bushings, seals, slides, scrubbers, housings, tanks, valves, washers, wear plates, bumper pads, chain wear parts, wear strip, slides, guides, wear liners, gaskets, tubing hoses, spacers, diaphragms, sprockets, etc.

PRODUCTS:

- Redco™ Chain Channel

- Redco™ Plastic Liners

- Redco™ Flexible PVC/Strip Door

- Redco™ Bushings and Bearings

- Redco™ Sprockets

- Redco™ Rubber Rollers and Roller Recoats

- Redco™ Seals & Gaskets

REDCO™ FEATURE APPLICATIONS & MATERIALS:

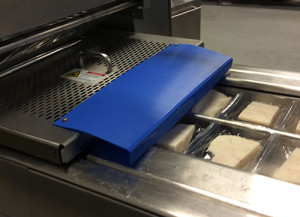

Redco™ Colored UHMW, Acetal & Nylon

White materials can be hard to visually detect if they have fallen into the production process. Fortunately white isn’t your only option in regards to FDA Approved UHMW, Acetal and Nylon materials. We also offer a variety of colors to make is easy to spot the slightest contamination. Blue materials being the most popular choice – because no food is blue.. Download PDF Brochure.

Red, blue, yellow, orange… you choose the color and we provide a cost effective solution.

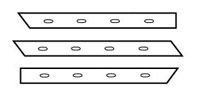

Redco™ UHMW Wearstrip

Redco™ UHMW Wearstrip offers superior protection for rails, chain and other moving machinery. Redco™ UHMW-PE wearstrip is easy to install, weighing about 1/8 that of steel.

It can outwear steel by up to 6 times and can reduce noise levels by 50%. Redco™ Black UHMW has good dielectric properties and will not absorb water or swell.

Available in various thicknesses and widths in 120? lengths.

B E N E F I T S

- Eliminates wear on the bottom and side rails

- Corrosion resistant

- Light weight

- Easy to install

Common Wearstrip Configurations:

Redco™ PVC Strip Door (Flexible Vinyl)

Redco™ PVC strip door and partitions contain heated or cooled air resulting in energy savings lost from unprotected openings. Dust, dirt and other contaminants also remain contained to reduce overall clean up costs. We offer a wide range of vinyl PVC for either pedestrian use and/or light traffic right up to heavy vehicle traffic such as fork-lift trucks.

Easy to clean, easy to replace and outstanding value. Redco™ Flexible PVC creates a safer and more productive work environment by providing protection from noise and harsh working environments while creating an easy to use, fully visible passageway for personnel, animals, product and machinery. Download PDF Brochure.

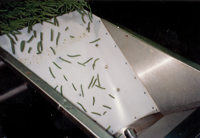

Redco™ UHMW Liner

Redco™ UHMW & Redco™ Acetal – Slicer Parts

Redco™ UHMW – Guides, Rollers, Wear-strips and Bearings

Polystone® and Sustarin® are registered trademarks of Roechling Engineering Plastics. Redco™ is a registered trademark of Redwood Plastics Corporation.