Redco 750 SXL

Designed for use in shock, sliding, low temperature, and gritty environments. Redco™ 750SXL has excellent self lubricating characteristics which make it ideal for applications which may experience dry running periods.

Durometer Hardness: 75D, 90R

Standard Color: Black

APPLICATIONS:

Bearings, bushings, wear plates, channel, liners, seals, hanger bearings, washers, liners, flotation cell parts, retainers, idler bearings, etc.

REDCO™ FEATURE APPLICATIONS:

Redco™ 750 SXL Inserts & Vacuum Seal

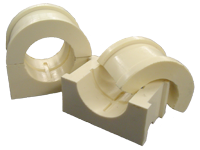

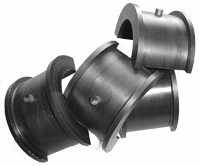

Redco™ 750 & 750 SXL Plastic Split Hanger Bearings

Split bearings allow for easier maintenance by simplifying replacement and are frequently used as support bearings for drive and screw-conveyor shafts. Typically, these industrial shafts are enclosed with a housing or conveyor trough. They are also commonly used in veneer and gypsum board dryers and fit all dryer configurations.

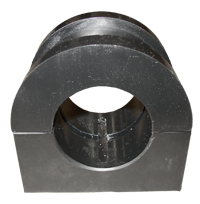

Redco™ 750 & 750 SXL Plastic Bushing & Bearing Materials

Durable polymer alloys capable of performing better than brass, bronzeor Babbitt!

- Self Lubricating

- Excellent for impact and shock application

- Exceptional wear life and resistance to corrosion

- Low temperature resistance to -80°F

Designed specifically for bulk handling, forestry, mining and transportation.

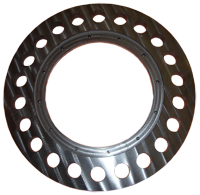

Redco™ 750 Sprockets

- Mill operating temperatures of -28°C (-18°F) through 40°C (100°F) present no problem for UHMW/PE or Redco™ 750.

- Redco™ 750 Sprockets are more dimensionally stable and can take higher temperatures (250°F).

- Redco™ 750 has a specific gravity of 1.3 (sinks in water) vs. UHMW specific gravity of 0.936 (floats in water).

The last two factors making Redco™ 750 Sprockets safe for mills where plastic contamination is a concern are:

- Better Chain Wear

- Lighter in Weight than Steel

- Requires No Bearing/bushing Idlers

- Helps Eliminate Noise

- Redco™ 750 has a memory allowing the teeth to hold their pitch better than UHMW.

- Corrosion, Rust And Chemical Resistant

- Very Cost Competitive