Biomass

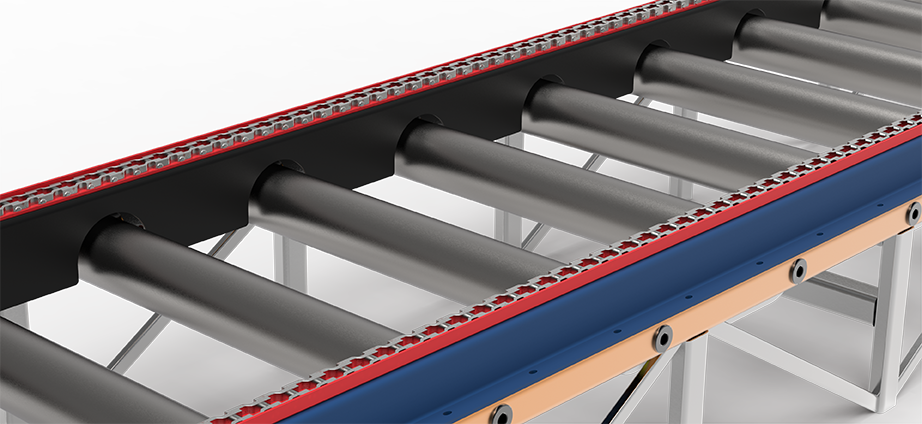

Regardless of the type of feed stock used within your facility, keeping material flowing and reducing maintenance is the best way to increase profits and improve efficiency. Using our performance plastic products such as Redco™ Polyurethane and Redco™ UHMW will improve performance, reduce wear and noise, and minimize product damage with little initial cost.

APPLICATIONS:

Bearings, conveyor liners, chain channel, bushings, gears, sprockets, roll coverings, wear plates, wear slides, screens, flights, gaskets, liners, seals, rollers, airlock wipes, stacking cones, box flights, etc.

REDCO™ FEATURE APPLICATIONS:

Redco™ 750, PVM Nylon & Titanium UHMW Channel/Angle

If UHMW channel or angle is being used to reduce chain and equipment wear and is bubbling, cracking or being replaced often due to heat, we have the perfect solution! Redco™ 750 Chain Channel doesn’t bubble, having a higher heat resistance and lasts considerably longer which reduces maintenance. The channel can be molded to any size to suit any chain size or conveyor system configuration. Request a quote.

Redco™ Synsteel Chip Screens

- Faster flow over screen

- Less problems with pitch build-up and freeze up

- Longer wear – up t 100% longer wear

- Fewer hang ups

TOP SCREENS

Usually done in 2 or 3 sections depending on the sizes: should be supported 18-24″ to allow for sag – if possible, 16″ centers would be ideal.

FINE SCREENS

Usually done in the same manner only with smaller holes – 3/8″ dia. & bigger, some 5/16″ done. The problem here is the thickness of 1/4″ material causing a plug up in the screen. This can be relieved by counter sinking the back of the holes.