Core Competences and Capabilities

Enhanced Performance Plastics Offerings

As a leading supplier and distributor of performance plastics for various industries, Redwood offers a wide range of plastic grades and types in multiple profiles, including sheets, rods, and tubes. For more specialized needs, Redwood also offers custom fabrications, liners, and machined parts.

Redwood’s highly-skilled team of fabricators and plastics specialists are always available to design, machine, mill, weld, route, and drill to produce prototypes, short runs, production runs, or maintenance parts for your business.

Whether you are an industry expert with a clear strategy, or unsure about the best product to meet your needs, Redwood’s highly specialized team and breadth of performance plastics is the perfect combination to ensure your project is a success.

Pre-production scheduling

Batch ordering available

On-shore manufacturing & staff

CNC Manufacturing at all sites

Comprehensive Rubber Solutions

Redwood supplies a wide range of rubber products in multiple commercial and premium grades, including vulcanized rollers, compression molded parts, rubber extrusions, custom lining, gaskets, and sheet rubber stock. Profile finishes including crowned, grooved, and specialty finishes are also available upon request.

When it comes to a material as diverse and extensive as rubber, it’s easy to feel uncertain about making the correct choice. That’s why Redwood’s team of rubber specialists are always available to help you choose the best Redco™ rubber solution to meet your needs.

Rubber extrusion

1000+ dies from 0-24″ available in-house

Metal lining and hand-building

Autoclaves & atmospheric curing

Rubber Compression Molding

15+ in-house presses from 100-7000 tonnes

Sheets in various grades and thicknesses

Custom gasket production

Local Urethane Manufacturing

From soft applications such as Deadplates, to TDI and MDI urethane parts including food grade, FDA compliant materials, Redwood’s latest design software and advanced equipment can produce urethane solutions in any color and durometer from 55A to 75D.

Redwood’s polyurethane machines are capable of handling projects big and small, with continuous casting at flow rates as high as 75lb/min. Whether your desired urethane solution is as light as a few grams or as heavy as 3000lbs, rest assured that our team of experts will create a formulation that meets your specific needs with high precision.

Part capabilities from 0 lbs

3000 lbs parts available

Maximum size of 15' x 15' x 50'

In-house spray urethane coatings

Various in-house molding styles

Unrivalled Technical Support

Since 1971, Redwood has prided itself on finding innovative solutions that reduce downtime and improve safety so you don’t have to. From the first call to the after-sale care, our team of over 200 employees are always committed to going the extra mile to ensure your needs are met every step of the way.

Whether by phone or email with our technical sales team, or on-site with our outside sales team, Redwood’s team of experts are always available help you discover a cost-effective solution for your application no matter its complexity.

Need help designing a part or discovering the most optimal material? Click the button below to book a free virtual or in-person consultation, or call an expert at 1-833-381-1195

200+ employees strong

30+ member sales team

Six full-time estimators on staff

Outside sales team to visit your site

Project managers for complex projects

Always available by phone or email

Quality Control & Product Development

A fundamental part of our organization is to support our customers with application and product design. Redwood offers material recommendations and provides optimal, cost-effective manufacturing processes. We can work with your existing design as well as assist in developing new custom parts. For your 3D printing needs, Redwood offers custom 3D printing for components, molds, or prototypes in a wide range of materials.

No matter your needs, Redwood’s team of quality control staff are always committed to ensuring your exact specifications are met and finding innovative ways to further enhance our product development capabilities.

Custom moulding

Reverse engineering

In-house quality control staff

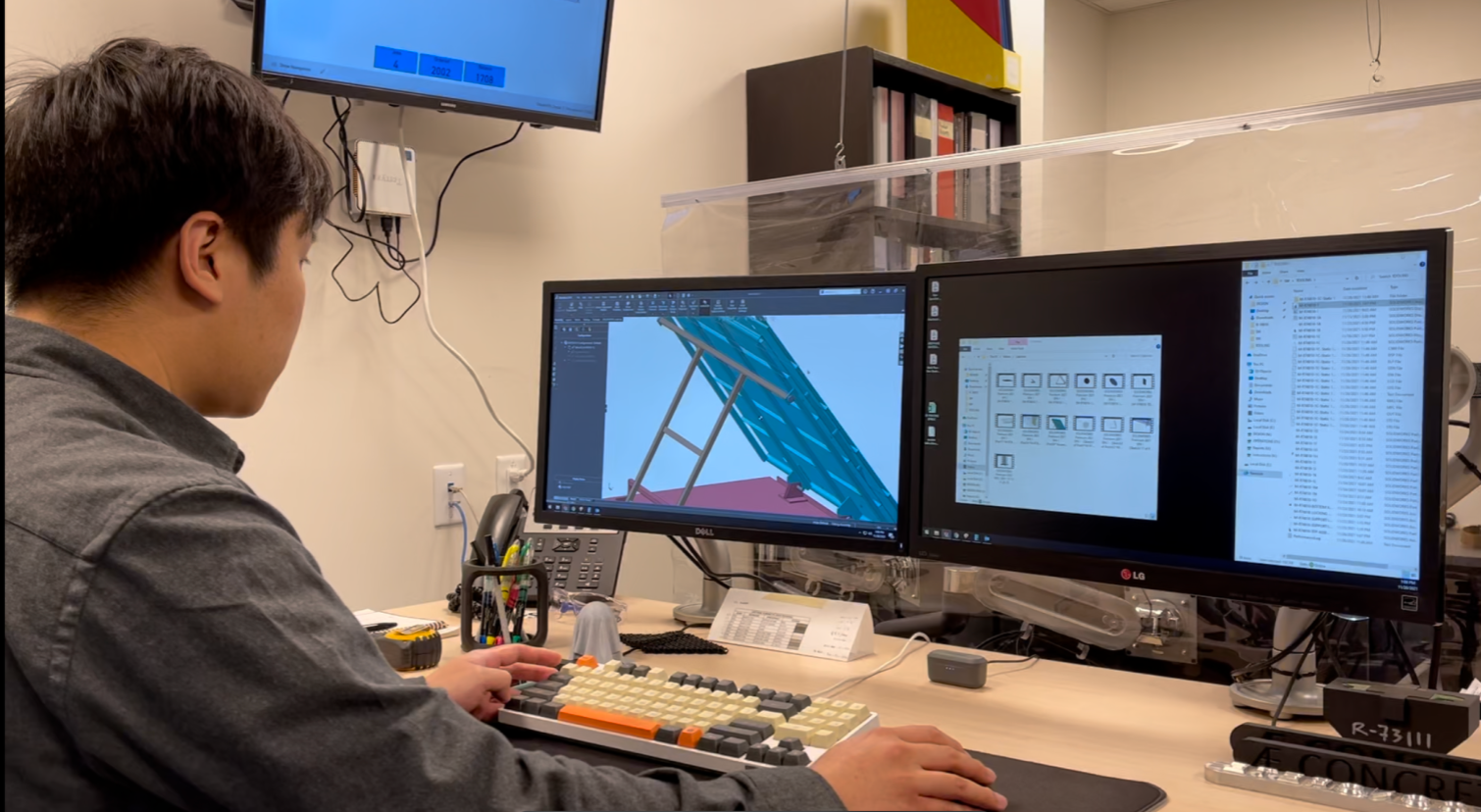

3D Modelling

Universal ASTM Testing Machine

In-House Machining & Fabrication

Each Redwood branch is equipped with a complete machine shop for single run items or for large quantity runs, including our CNC Machinery that allows us to manufacture in-house molds and cut precision parts.

Redwood’s team of over 20 highly-skilled fabricators can bend, form, cut-to-size, drill, or weld almost any plastic or rubber material to your exact specifications.