Polyurethane

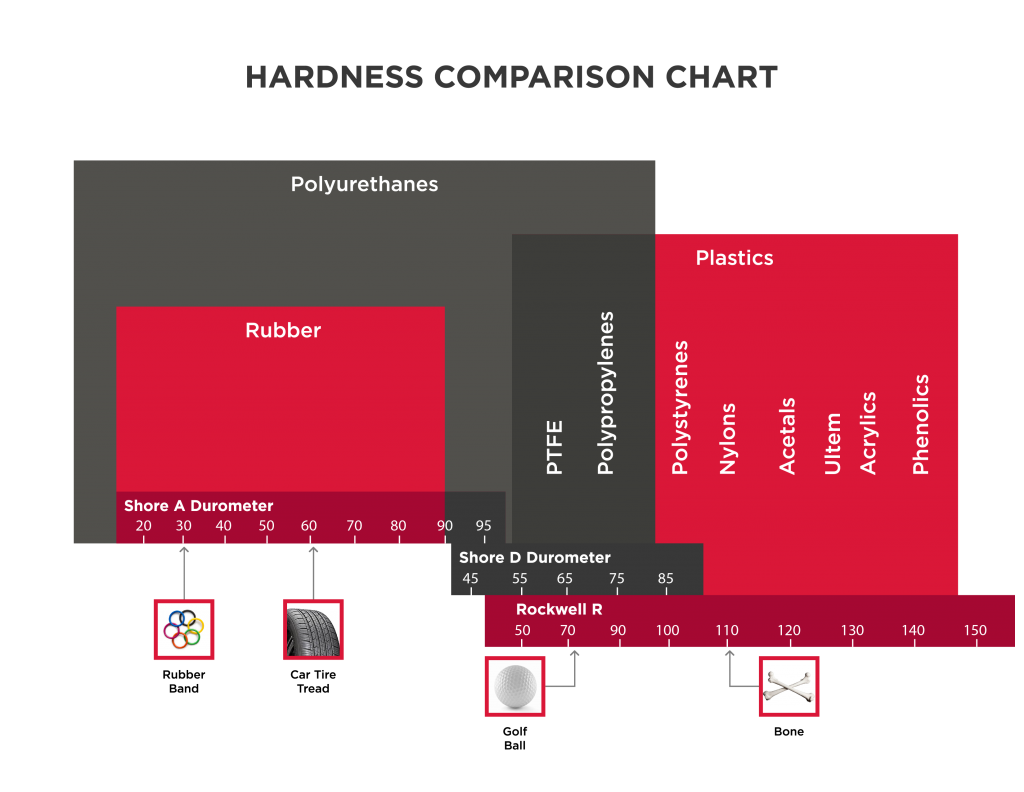

One of the most unique characteristics of this material is its broad hardness range, from eraser-soft to bowling ball hard. The hardness of polyurethane is governed by the molecular structure of the prepolymer and not by the addition of plasticizers or fillers.

Polyurethane combines the toughness of metal with the elasticity of rubber and has the ability to withstand the most severe abuse.

Due to its remarkable impact and abrasion resistance, parts made from polyurethane elastomers will often outwear rubber, plastic, and metal by margins of 20 to 1.

Other important characteristics include extremely high flex life, cut resistance, load bearing capacity (2500 PSI for Redco™ 750, Redco™ 750XL, and Redco™ 750SXL) and outstanding resistance to weather, ozone, oxygen, and radiation. It performs well from -80 F to +200 F and has excellent resistance to oil, gasoline, and most solvents.

Costly down-time and maintenance expense can be avoided by substituting polyurethane for materials that are not performing to satisfaction.

The unique properties of Redco™ Polyurethane have opened new horizons for the engineer who is designing products for the future.

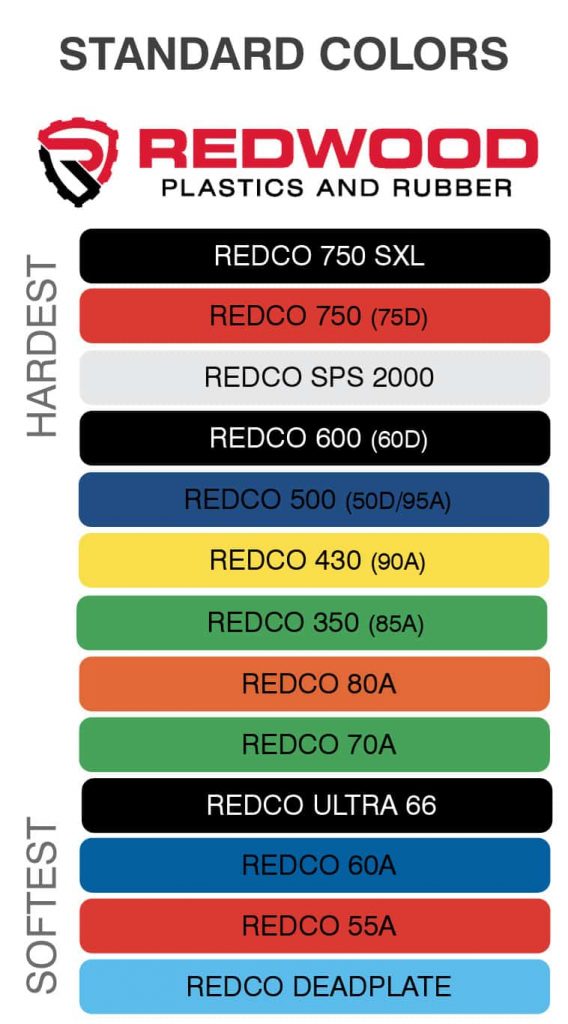

Redco™ Polyurethane Available Grades:

- Redco™ Deadplate

- Redco™ 55A

- Redco™ 60A

- Redco™ Ultra 66

- Redco™ 70A

- Redco™ 80A

- Redco™ 350 (85A)

- Redco™ 430 (90A)

- Redco™ 500 (50D/95A)

- Redco™ 600 (60D)

- Redco™ 750 (75D)

- Redco™ 750SXL

- Redco™ SPS-2000

- Redco™ Vypur Fras

Redco™ Polyurethane Industry Products: