Redco Tivar

Redco™ Tivar®* is noted for its performance in promoting material flow of congested materials due to its low surface friction. Redco™ Tivar® liners are the perfect solution when you need to reduce or eliminate arching, ratholing and erratic material flow challenges. The Redco™ Tivar®* product line has a variety of custom formulations to suit many applications to reduce noise, prevent hang ups, bridging and ratholing, eliminate static and decrease wear on equipment.

- Abrasion, chemical and corrosion resistant

- Low coefficient of friction

- No moisture absorption

- Reduces or eliminates arching, ratholing and erractic flow

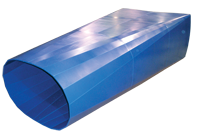

Color: Blue

Sheet Size: 48″ X 120″

Sheet Thicknesses: 1/8 to 2″

(Custom colors are available)

Cut-to-Size, Fabrication and Machining is Available.

APPLICATIONS:

Belt skirting, chute liners, conveying components including; bearings, belt guides, chain guides, curves, guide rails, wearstrips, dead plates, diverter bars, guide rollers, hitch plates, hopper liners, liners for gravity flow applications, roller covers, transfer plates, under belt wearstrips, belt scrapers, bunker liners, chain conveyor flights, chute liners, conveyor skirting, cyclones, drag chain conveyor liners, dragline buckets, dust collection hopper liners, front end loader bucket liners, hopper liners, off-road truck beds, pugmill paddles, railcar liners, reclaimer buckets, screw conveyor liners, self-unloading ships, silo liners, slider beds, storage bin liners surge bin liners, transfer chute liners, under chain guides, wearstrips, vibrating bin, dischargers, vibratory feeder liners, etc.

PREMIUM GRADES TO SUIT EVERY APPLICATION:

The Redco™ Tivar®* product line has a variety of custom formulations to suit many applications to reduce noise, prevent hang ups, bridging and ratholing, eliminate static and decrease wear on equipment. Specialty formulations include:

Redco™ Tivar® 88

A premium lining material for bulk material handling, Redco™ Tivar® 88 promotes flow of cohesive or non-free flowing materials due to its low surface friction. Redco™ Tivar® 88 liners are the perfect solution to reduce or eliminate arching, ratholing and erratic material flow challenges.

Redco™ Tivar® Dryslide

Ideal for dusty environments, Redco™ Tivar® Dryslide is electrostatic dissipative which eliminates shock due to friction. Redco™ Tivar® Dryslide is also corrosion-resistant, self-lubricating (dry lubricant formulation) with no moisture absorption.

Redco™ Tivar® H.O.T.

Formulated to maintain key performance properties in a variety of industrial manufacturing environments where temperatures range up to 275°F. In many applications, Redco™ Tivar® H.O.T will last up to 10 times longer in higher temperature environments and has excellent wear and release characteristics.

Redco™ Tivar® Ceram P®

The ultimate material for high load, high speed and severe sliding abrasion applications. Composed of virgin polymer and premium additives, Redco™ Tivar® Ceram P® is a shatter-resistant alternative to ceramics, reducing wear and machine maintenance downtime.