Aggregate, Asphalt & Ready Mix

Hard rock quarrying and sand and gravel processing equipment endure aggressive environments and as one of the most utilized products in the world, production speed and downtime can effect the bottom line drastically. Redwood Plastics and Rubber has materials and applications that endure the crushing, shaping, screening and washing of crushed stone, gravel, and sand.

APPLICATIONS:

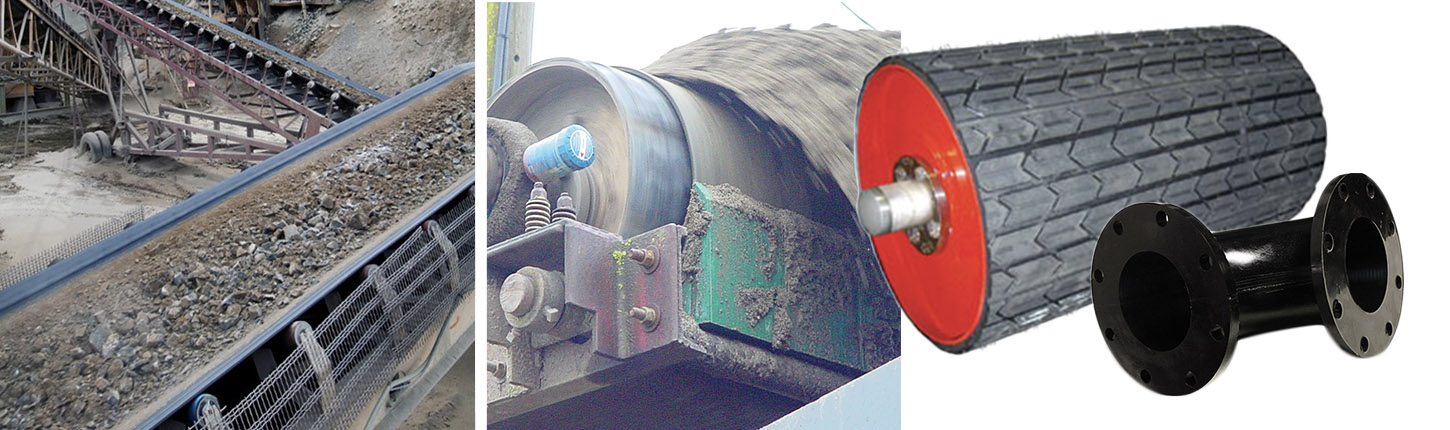

Belt scrapers, aprons & skirts, urethane impact bars, classifier elbow spouts, classifier shoes, valve-guide seals, coated wheels (rubber/urethane), conveyor belt training rollers, dead box/pocket liners (urethane/rubber lined), discharge spouts (socks & sleeves), dust cover seals for screen decks, urethane pipe, hopper liners, impact pads, belly pads, pulley lagging, screen tension rails, U-channel, wear covers, wear tiles, abrasion resistant chute liners, ball mill liners, bumper boards, conveyor system components, feed box liners, ore car cushions, skip liners, slurry pump liners, truck charge hopper, discharge chute liner, etc.

PRODUCTS:

- Redco™ Sheaves and Pulleys

- Redco™ FRP Grating

- Redco™ Engineered Outrigger Pads

- Redco™ Truck Liners

- Redco™ Plastic Liners

- Redco™ Rubber Liners

- Redco™ Rubber Rollers and Roller Recoats

- Redco™ Green Screens

- Redco™ Switchblade™ – Belt Scraper Blade

REDCO™ FEATURE APPLICATIONS:

Redco™ Premium Liners for Chutes and Hoppers

Redco™ Polyurethane liners are designed to be easily bolted into your chute or hopper.

- Protect your equipment (substrate)

- Ease of installation

- Abrasion and corrosion resistant

- Eliminates nearly any sticking or material bridging problems

- Produced in modular shapes or standard sizes

- Available in a variety of thicknesses

Bolt in-place liners are fastened in place by bolting to your substrate. The liners are utilized throughout the concrete industry to provide long lasting protection for steel substrates, liners can be installed in a variety of ways, please contact us to determine the most cost-effective, long wearing installation method for your application.

Applications: transition hoppers, discharge chutes, feed boxes, trough linings, etc.

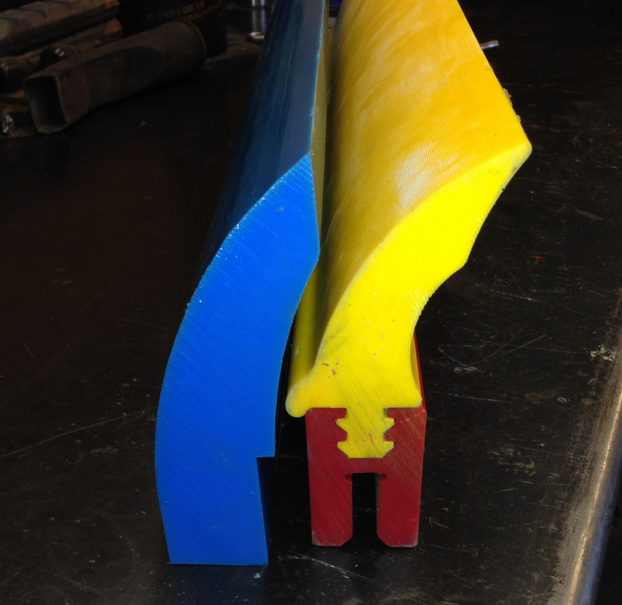

Redco™ Switchblade (Belt Scraper / Belt Cleaning)

Redco™ Switchblade™ is an innovated new conveyor belt cleaning system that replaces traditional scraper blades and belt wipers. The patented design uses a re-usable mounting base and a replaceable scraping blade section that can be quickly changed during routine maintenance. The advantage of Redco™ Switchblade™ extends beyond the design, as field trials show it outlasts the competition by more than 3x in head-to-head competition and the innovative blade geometry starts cleaning your belts faster, with less “break-in” period.

Available in a wide range of belt sizes, Redco™ Switchblade™ replacement blades are available in bulk 120” long sections for improved yield and custom cutting on site. Supercharge your belt cleaning system with Redco™ Switchblade™.

Download PDF Brochure with Specifications

Redco™ Truck Charge Hopper & Discharge Chute Liner

Mixing concrete is a difficult process, and is especially taxing on your mixing equipment. In recent years, the value of lining equipment has become readily apparent; however, if you’re not using the proper lining materials, lining your equipment can cause excessively long shut-downs.

Urethane liners resist sticking and build-up inherent with rubber and steel type liners, provide easier cleanup, and wear longer than steel.

- Fast, Bolt In Installation

- No Seams to Disrupt Flow or Collect

- Provides easier loading of Mixer and less time at the slump rack.

- Lightweight and outperforms steel.

- Economical—protects metal hopper and main chute against wear.

Redco™ Urethane Pan Mixer Liners

Protect your pan liner and reduce maintenance cost with a Redco™ Urethane pan mixer liner.

- Ease of clean-up between batches (breaking loose dried concrete)

- Reduce or eliminate sticking and buildup

- Can outlast steel liners by 2 – 4 times

- Reduces noise levels

- Reduced downtime and maintenance

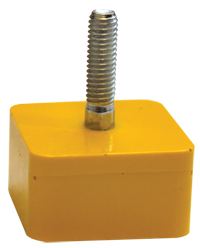

Redco™ Urethane Wear Pads

Redco™ Urethane Screw Conveyor Flight Wear Pads are the solution to the abrasion problems inherent in screw conveyor applications. The advantages to urethane wear pads are:

- Urethane won’t rust or corrode

- Lightweight = easy to install with less wear on equipment

- Redco™ urethane classifier shoes will return to their original shape if bent or distorted

- Available in a variety of styles and replacement sizes

Redco™ Urethane Impact Bars

Redco™ Urethane Impact Bars feature a solid design that prevents belt damage and provides exceptional impact and wear resistance.

- Superior belt support

- Significantly longer life

- Lower impact bed maintenance requirements

- Less wear and tear on your conveyor belt

- Absorbs and cushions impact

- Reduces belt and bed maintenance costs

Redco™ Truck Liners

Redco™ Truck Liners virtually eliminate material hang up concerns in a variety of environments and applications; including gravel, road cinders, wet and frozen soil and limestone. Withstanding high impact; two times the wear of steel and four times the wear of aluminum.

Available in Redco™Virgin UHMW, Redco™Reprocessed UHMW, Redco™ X-Static, Redco™ Titanium, Redco™ Tivar & Redco™ Quicksilver.

Redco™ Vypur™ Polyurethane Pipe Sections For Slurry & Abrasive Applications

Less Maintenance, Exceptional Life

Redco™ VYPUR™ Polyurethane Pipe Sections, Elbows, Flanges and Fittings are used to replace steel, HDPE and rubber-lined pipe in aggressive abrasion and corrosive applications.

100% manufactured in North America and available in a wide range of configurations.

Field testing supports Redco™ VYPUR™ Polyurethane Pipe Sections outlasting traditional piping by a factor up to 6X, saving costly downtime and maintenance expense.

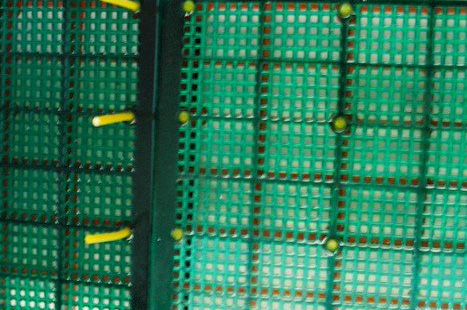

Redco™ Green Screen

PRODUCT LINE:

- Polyurethane Modular Screen Panels

- Polyurethane Frame Protector and Clip Rails

- Screen Wear Surface

- Rigid Polymer Subframe

- Tension Screen Subframe / Replaceable Modular Panel Surface

- Lip Panels

- Landing or Impact Panels

- Side Liners

Redco™ Cable Sheaves & Pulleys

Redco™ Nylon Cable Sheaves & Pulleys offer high load bearing capabilities (up to 4000 PSI), are light weight, self lubricating and have a low co-efficient of friction. Redco™ Nylon is easily machined and is both an outlasting and outperforming replacement for metals and other plastics. A heat stabilized formulation is available for applications with a maximum continuous operating temperature of 260ºF.

• Ultimate compressive strength is 15,000 psi

• Bearing compressive strength is 4,000 psi

Learn more about Redco Sheaves & Pulleys – here.

Redco™ Pads & Bumpers

Redco™ Pads & Bumpers Constant banging and scraping will wear out equipment prematurely. Redco™ Plastics are engineered for the toughest applications to absorb impact and prolong equipment life. We have developed numerous parts for trucks and shovels such as:

Redco™ Body Pads, which have been designed to replace traditional rubber pads, provide longer wear life and don’t permit the impregnation of rocks. The pads bolt or weld directly to the bottom of the truck box to protect the frame from shock, vibration, and wear.

Redco™ Urethane Bumpers, which are available in many custom sizes, protect the truck body from banging ladders, wheel chocks, etc. while the truck is in motion.