FRP Grating

Redco™ FRP Grating provides durability with extremely high strength and stiffness. Due to its high load capacity it can be used with confidence in applications where wide support spans are required. Redco™ FRP Grating is also corrosion resistant and non-conductive making it ideal for applications where electrical current or chemicals may be present. Redco™ FRP Grating is low maintenance with a low cost of installation.

Grating varieties available include: DURADEK®, DURAGRID®, DURAGRID® Heavy Duty, DURAGRID® Phenolic, REDCO™ Molded Fiberglass Grating, and DURATREAD™ molded fiberglass stair tread covers.

• Anti-slip

• Impact Resistant

• Weatherproof

• Non-sparking

• Lightweight

• Easy to install

• Non-magnetic

• Non-skid surface

• Fire retardant

• Non-conductive

• Maintenance free

• Corrosion resistant

REDCO™ FEATURE APPLICATIONS:

Redco™ FRP Grating Walkways, Stairs & Platforms

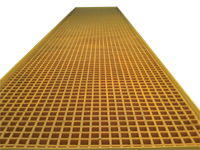

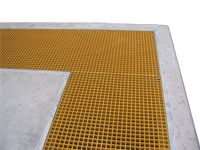

Redco™ Molded Fiberglass Grating

Redco™ Molded Fiberglass Grating is the chemical resistant flooring choice for many industrial applications. The high resin content provides excellent corrosion resistance and requires very little maintenance.

The strong mesh grating panel allows efficient on-site cutting to minimize grating waste. Molded grating is significantly lighter in weight than metallic gratings.

Standard Redco™ Molded Fiberglass Grating has a concave profile on the upper surface for skid resistance. Grit tops (non-slip) are standard.

Sizes and Availability

REDCO™ MOLDED FIBERGLASS GRATING is available in a variety of sizes:

- 1-1/2″ thick 1-1/2″ Square (48″ x 96″, 48″ x 120″, 48″ x 144″) with a non-slip surface

- 1-1/2″ thick Mini-Mesh (48″ x 144″) with a non-slip surface

Standard colors available are: dark gray, green and yellow. Other colors are available by special request.

Custom sizes are available upon request.

Load Bearing Capacity

Load capacity charts for uniform load, concentrated panel load, concentrated line loads.

Redco Mini-Mesh Dock / Boardwalk for Marina

Other FRP Grating Varieties:

DURADEK® Standard Pultruded Grating

DURADEK® is a standard pultruded grating product that is available with individual bearing bars in either 1″ or 1-1/2″ “I” shapes or a 2″ “T” shape. DURADEK® is a flame retardant product utilizing a polyester or vinyl ester resin. The bearing bars use both longitudinal and multidirectional reinforcements as well as a synthetic surfacing veil to provide unequaled corrosion resistance.

DURAGRID® Custom Grating

DURAGRID® custom grid and grating systems are designed to accommodate specific applications that cannot effectively be met by a standard fiberglass grating. DURAGRID® offers options such as selection of bar spacing (which creates varying open space in the grating or grid), bar shape, cross-rod placement, custom fabrication, custom resin or color.

DURAGRID® Heavy Duty Grating

DURAGRID® Heavy Duty Grating is a pultruded bar type grating that can be designed and used like traditional metal grates. The solid individual bearing bars are designed to take heavy wheel traffic such as fork lifts, tow motors and truck traffic. Heavy duty grating is constructed of the same type composite used in the other DURAGRID® products.

DURAGRID® Phenolic Grating

DURAGRID® Phenolic grating is a dramatic innovation for markets where fire safety is a major concern; it offers superior resistance to flame and high temperature with low emissions of smoke and toxic fumes. The nonflammable nature of phenolics enable phenolic grating to withstand higher temperatures than polyester or vinyl ester for extended periods of time without major structural damage. Combined with low thermal conductivity, this provides fire protection not available with alternate materials. DURAGRID® Phenolic grating was the first composite grating to receive U.S. Coast Guard approval. It is accepted for use in locations and applications as allowed in the U.S.C.G. Policy File Memorandum 2-98 for fire retardant grating meeting structural fire integrity Level 2(L2).

Designing with Pultruded Fiberglass Grating

The bearing bars are assembled into 12 panel sizes; 3-, 4- and 5-foot widths in each of 8-, 10-, 12- and 20-foot lengths. Standard panels come with cross-rod spacings of 6″ or optional 12″ on center.

Materials of Construction

Redwood Plastics offers eight resin systems for its molded grating to accommodate different applications to ensure optimum utilization of grating.

|

Resin Type

|

Resin Base

|

Description

|

Corrosion Resistance

|

Flame Spread Rating ASTM E84

|

Available colors

|

Max. Oper.

Temp |

|

Type VEFR-25

|

Vinyl Ester

|

Superior Corrosion Resistance and Fire Retardant

|

Excellent

|

Class 1, 25 or less

|

Dark Gray, Orange

|

230°F

(110°C)

|

|

Type VEFR-10

|

Vinyl Ester

|

Superior Corrosion Resistance and Enhanced Fire Retardant

|

Excellent

|

Class 1, 10 or less

|

Dark Gray

|

230°F

(110°C)

|

|

Type IFR-25

|

Isophthalic Polyester

|

Industrial Grade Corrosion Resistance and Fire Retardant

|

Very Good

|

Class 1, 25 or less

|

Dark Gray, Green

|

221°F

(105°C)

|

|

Type FG-30

|

Isophthalic Polyester

|

Food Grade Corrosion Resistance and Fire Retardant

|

Very Good

|

Class 1, 30 or less

|

Light Gray,

Light Green |

221°F

(105°C)

|

|

Type CFR-25

|

Ortho

|

Moderate Corrosion Resistance and Fire Retardant

|

Moderate

|

Class 1, 25 or less

|

Green

Yellow Light Gray Dark Gray |

212°F

(100°C)

|

|

Type MP-5

|

Phenolic resin

|

Low Smoke and Superior Fire Resistance

|

Very Good

|

Class 1, 5 or less

|

Reddish-Brown Phenolic painting of the grating can be performed to obtain a gray or red finish

|

356°F

(180°C)

|

|

Type

IFR-10 |

Isophthalic Polyester

|

Industrial Grade Corrosion Resistance and Extra Fire Retardant

|

Very Good

|

Class 1, 10 or less

|

Custom

|

221°F

(105°C)

|

|

Type

O-AN |

Ortho

|

Moderate Corrosion Resistance

|

Moderate

|

No

|

Green, Yellow, Light Gray,

Dark Gray |

212°F

(100°C)

|

FRP GRATING INDUSTRIES:

| Agricultural | Air Pollution Control | Brewing and Distillery |

| Caustic and Chlorine | Dairy and Food Processing |

Electroplating and Picking |

| Effluent Lines | Chemical Fertilizers | Fisheries |

| Food and Electric | Heating & Plumbing | Air Conditioning |

| Chemicals | Metal Finishing | Petrochemicals |

| Pigments and Dyes | Power Plants | Pulp and Paper |

| Rubber | Soap and Detergents |

Sewage Treatment |

| Textiles | Water Treatment | Materials Handling |

| Hospitals | University and Industrial Lab |

Solvents and Organic Chemicals |

APPLICATIONS:

| Flooring | Platforms |

| Walkways | Assembly Lines |

| Trench Covers | Stairs |

| Catwalks | Ramps |

| Gully Covers | Bridges |

| Screens | Jetties |

| Track Crossing | Vent Grills |