Plastic Comparisons

We can help you determine which plastic will preform optimally for your application; whether it is under water, subjected to high heat or in contact with harsh chemicals, there is likely a plastic variety that will outlast steel, iron, rubber and many other alternative materials.

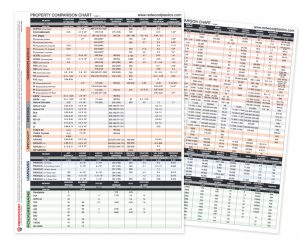

To compare our most popular plastics by their physical properties please reference our Property Comparison Chart (PDF).

SLICKNESS (Most to Least)

Redco PTFE (Teflon®)

Redco UHMW

Redco Tuffkast

Redco Polyurethane (Redco 750SXL)

Redco Nylon

Redco Polyurethane (Redco 750)

Redco Phenolic

MAXIMUM TEMPERATURE (500+ F) (260+ C)

Redco PTFE (Teflon®) (500 – 600°F)

Redco Phenolic (400 – 500°F)

Redco Nylon (240 – 275°F)

Redco Tuffkast (220 – 240°F)

Redco Polyurethane (200 – 240°F)

Redco UHMW (160 – 180°F)

HARDNESS

Redco Phenolic

Redco Nylon

Redco Tuffkast

Redco Polyurethane (Redco 750 & Redco 750SXL)

GLAZING

Breakage Resistant Windows

(Redco Acrylic/ Redco Polycarbonate)

Security Windows

(Redco Acrylic / Redco Polycarbonate)

LOAD STRENGTH (P.S.I)

Redco Phenolic (10000)

Redco Nylon (4000)

Redco Tuffkast (3800)

Redco Polyurethane (3000)

Redco UHMW (500 – 800)

Redco PTFE (Teflon®) (500)

IMPACT STRENGTH

Redco Polyurethane

Redco Tuffkast

Redco Phenolic

Redco UHMW

Redco Nylon

Redco PTFE (Teflon®)

SHOCK & VIBRATION

Redco SVI PADS

(KRAFT MILL) PULP SAFE

Redco Synsteel (Redco UHMW)

Redco SPS-2000 (Redco POLYURETHANE)

LOW WATER ABSORPTION

Redco Acetal

Redco UHMW