Bushings & Bearings

Durability Meets Performance

Manufactured for bulk handling, forestry, mining, and transportation, Redco™ Plastic Bushing & Bearing materials are built from durable polymer alloys that can outperform traditional brass, bronze, & Babbitt bearings.

Redwood offers a wide range of bearing materials that will deliver reliable,

high-quality performance no matter the situation. Whether your application contains shocks, vibrations, extreme temperatures, high

pressure, high velocity, or chemicals, Redco™ Bushings & Bearings deliver durability and dependability.

Redco™ Bushings & Bearings Features

Self-lubricating

Excellent shock & impact absorption

Exceptional wear life

Resists temperatures to -80°F

Eliminate grease contamination & damage

Excellent corrosion resistance

When to Use Redco™ Materials

When it comes to using plastics for various applications, it may be difficult to determine which material to use, especially with bearings and bushings. Below is a quick overview as to which plastic type is best suited for certain environments however we are happy to help you choose which materials is best. Contact us.

Please note: Plastic Clearance/Tolerance is subject to many variables (i.e. moisture, cold, heat) when being machined for specific applications. If lubrication is supplied to a plastic bearing, the load and life are greatly increased dependent on the type and volume of lubricant.

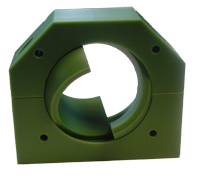

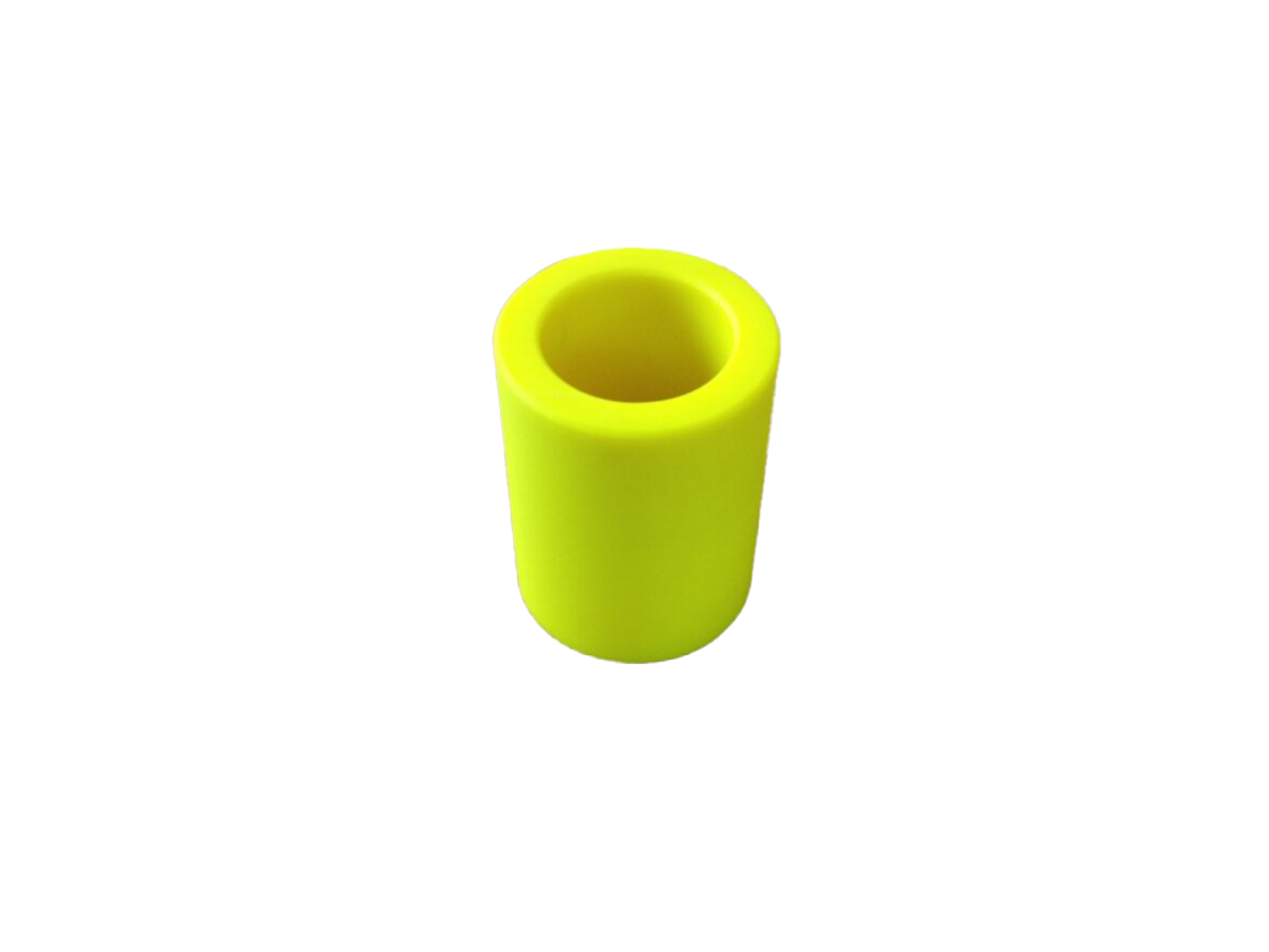

Redco™ Polyurethanes

Best used in applications where shock, vibration, impact and lower or freezing temperatures are of a concern. Urethane is the superior option here due to its elasticity.

Redco™ 750 / 750 XL / SXL

Redco™ 750 / 750 XL / SXL is typically used as hourglass bearings, sprocket bushings, kicker arm bushings, pivot bearings, SN insert bearings, and hanger bearings.

Maximum PSI approx. 2500.

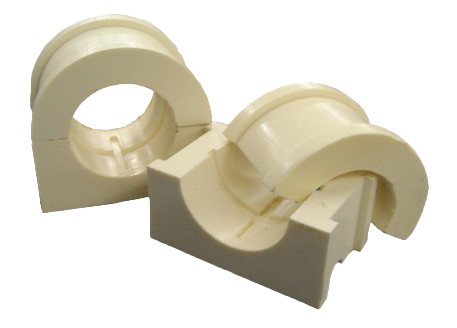

Redco™ Cast Nylons

Best used in applications of higher velocity, pressure, and ambient temperature (poor against the cold and impacts). Redco™ Cast Nylons are typically used as kiln bearings, pivot bearings, sheaves, winch bushings, tail shaft bearings, and hanger bearings.

Maximum PSI approx. 4000.

Redco™ Phenolics

Best used in applications where heat, cold, high pressure, and velocity are of concern. Redco™ Phenolics are typically used as: Press roll bushings, mitre box bushings, sheave bearings, high-load kiln bearings (30 000+), boom pivot bearings, and barker bearings.

Maximum PSI approx. 10,000

Redco™ TEFLONS

Typically used in applications where extreme heat, harsh chemicals, moisture and corrosion are of concern. Redco™ TEFLONS are typically used as veneer dryer bearings, non-stick rollers, food handling, and chemical parts.

Maximum PSI approx. 500, dependent on additives.

Redco™ UHMW

Best used in applications containing light loads, chemicals, cold, and some impacts. Redco™ UHMW is typically used as skate wheels, light duty bearings, and food and chemical parts.

Maximum PSI approx. 500-800, dependent on additives.