Redwood Plastics has the knowledge and experience to know what materials work best in a variety of industrial applications. Not all plastics are created equal and we will help you determine which material is the best for your application. Just like we did for this cedar mill…

A “motor mount” UHMW bracket was wearing prematurely in a cedar mill application. It was a 2 piece UH bearing that supported a diverter arm assembly that rotates about 45 degrees. It was operated by an air system which had very fast movement and impact. The shaft was also a Schedule 80 Pipe that had the arms welded on in-house and thus was not perfectly straight. The shaft had five mount points and the original parts were replaced every 6-8 weeks.

They wanted a solution that would take the impact and also compensate for the pipe variation.

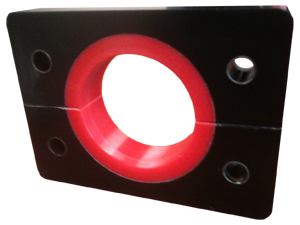

The solution was a Redco urethane unit design with a 750 (hardness) inner ring for the wear point, an 80A(hardness) outer shell for the impact with metal inserts to allow for a solid mount. The new Redco urethane parts vastly outlasted the UHMW parts and over 100 parts have now been replaced with the new Redco urethane bracket.

Contact us today about your application:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684