Redco™ Gladiator Snow Plow Blades

- Outlasts Steel by up to 400%.

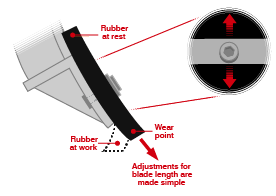

- Resilient Rubber* compound adjusts easily to road surface irregularities. Will not gouge asphalt, concrete or tar-gravel surfaces. Rubber blades won’t damage pavement markers.

- Provide quick, clean removal of heavy snow and slush.

- Safer at High-Speed runs. Clearing highways and airport runways in the shortest possible time

- Reduced Impact Shock. Rubber plow blades absorb impact, shock & vibration. Less stress is transmitted to the plow and vehicle resulting in longer life for your fleet.

- Lowered Maintenance Costs. Rubber blades require replacing less frequently than steel blades, resulting in fewer man-hours and less downtime.

**Also available in Redco™ Reprocessed UHMW

ALSO AVAILABLE:

Redco™ Polyurethane Cutting Edges

Contractor Benefits Include:

- Polyurethane exhibits better abrasion characteristics than rubber and most metals.

- Polyurethane is resilient, and therefore absorbs impacts and conforms to the surface being plowed rather than damaging the plowing surface, making it the ideal choice for use on concrete, parking garages, brick, pavers, cobblestone, or any other uneven surface.

- Polyurethane cutting edges reduce driver fatigue and equipment wear by minimizing blade and equipment vibration.

- Polyurethane cutting edges are very quiet in operation, making them ideal for use in residential areas and hospitals.

Airport Benefits Include: (including the above)

- FAA regulators strongly suggest that airport snowplows be equipped with urethane cutting edges

- Polyurethane cutting edges can save you money in the long run. Polyurethane cutting edges are less likely to rip out or damage submerged lighting and pavement markings.

- Reduce litter on runways-polyurethane cutting edges will eliminate metal shavings that are encountered when using metal cutting edges.

General Recommendations When Using Polyurethane Cutting Edges:

- For demanding applications we recommend using 1-1/2″ thick cutting edges.

- We recommend using 1-1/2″ vs. 1″ cutting edges for plows 102″ or larger.

- To maximize the life of your cutting edge skid shoes should be utilized. If skid shoes are not being utilized, a 1-1/2″ cutting edge should be used.

- When mounting a new cutting edge, the overhang below the moldboard should not exceed the thickness of the cutting edge.

- When mounting a new cutting edge, the old steel cutting edge or piece of flat stock steel should be mounted on top of the new urethane cutting edge, acting as a large washer.

- Plowing speeds in excess of 35 mph are not advised.

Lightweight, durable polyurethane spinners are an ideal replacement for worn stock spinners as aggregate (ie: sand, salt, etc…) will not adhere to the polyurethane surface. And unlike the metal variety, polyurethane spinners resist impact damage and will never rust. Open hub or Closed hub, most configurations available.

Compaction Drum Scraper Blades

Downtime and performance are two of the most important factors with any construction equipment. Let our experience work for you.

Redwood Plastics and Rubber has developed a proven scraper blade that is formulated for maximum performance and minimum downtime