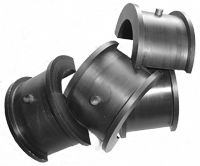

Bushings and Bearings

- Self Lubricating

- Excellent for impact and shock application

- Exceptional wear life and resistance to corrosion

- Low temperature resistance to -80°F

- Eliminate grease contamination or damage to products

When it comes to using plastics for various applications, it may be difficult to determine which material to use, especially with bearings and bushings. Below is a quick overview as to which plastic type is best suited for certain environments however we are happy to help you choose which materials is best, contact us.

PLEASE NOTE: Plastic Clearance/Tolerance is subject to many variables (i.e. Moisture, Cold Heat) when being machined for specific applications. If lubrication is supplied to a plastic bearing, the load and life are greatly increased dependent on the type and volume of lubricant.

WHEN TO USE REDCO BEARING MATERIALS

REDCO POLYURETHANES

- Applications where shock, vibration, impact and lower or freezing temperatures are of a concern.

- Urethane is optimal due to its elasticity in the applications above.

- Absorbs 1.3% moisture.

- PDF Specifications – Hanger Bearings

- PDF Brochure – SN Bearings/SAF Bearing Inserts

REDCO 750 / 750 XL / SXL

- Approx. 2500 PSI is at the top of its limitations

- Typically used as: Hourglass Bearings, Sprocket Bushings, Kicker Arm Bushings, Pivot Bearings, SN insert Bearings, Rollers, Barker Bearings, and Hanger Bearings.

- PDF Specifications – Hanger Bearings

- PDF Brochure – SN Bearings/SAF Bearing Inserts

REDCO CAST NYLONS

- Applications of higher velocity, pressure and ambient temperature (will not take a lot of cold and impact)

- Absorbs 3% moisture.

- Approximately 4000 PSI is at the top of its limitations.

- Typically used as: Kiln Bearings, Pivot Bearings, Sheaves, Winch Bushing, Tail Shaft Bearings, Hanger Bearings

- PDF Specifications – Hanger Bearings

REDCO ACETAL

- Basically the same as nylon except it absorbs considerably less moisture and is slightly harder.

REDCO PHENOLICS

- Applications where heat, cold, high pressure, impact and velocity are of concern.

- Absorbs 1% moisture.

- Approximately 10 000 PSI is near the top of its limitations.

- Typically used as: Press Roll Bushings, Mitre Box Bushings, Sheave Bearings,High Load Kiln Bearings (30 000+), Boom Pivot Bearings, Barker Bearings.

REDCO PTFE

- Generally used in applications where extreme heat (300+), harsh chemicals, moisture and corrosion are of concern.

- Approximately 500 PSI is at the top of its limitations dependent on additives.

- Absorbs no moisture.

- Typically used as: Veneer Dryer Bearings, Non-stick Rollers, Food Handling and Chemical Parts.

- PDF Specifications – Hanger Bearings

REDCO UHMW

- Application of light load, chemicals, cold, some impact.

- Absorbs no moisture.

- Approximately 500 – 800 PSI is at the top of its limitations dependent on additives.

- Typically used as: Skate Wheels, Light Duty Bearings, Food and Chemical Parts.

- PDF Specifications – Hanger Bearings

- PDF Specifications – Bearing Inserts