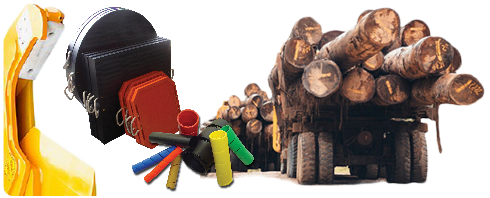

Logging

Cut costs, reduce wear and increase productivity! Redwood Plastics specializes in a variety of applications including; loader parts, truck parts, bushings, bearings, hose wrap and outrigger pads.

Redco™ Plastic and Rubber applications have been proven to decrease downtime, and reduce noise, vibrations and power consumption! Increase production to its fullest potential by adding Redco™ Plastic and Rubber products; bringing benefits and savings to your site.

APPLICATIONS:

Loader parts, bumpers, bushings, spacers, washers, safety windows, convex mirrors, hose wrap, outriggers pads, slides, hose saddles, trunion bushings, truck parts, tree spars, tree shear cushion stops, grapple bumpers and bushings, etc.

REDCO™ FEATURE APPLICATIONS:

Redco™ Bushings & Bearing Materials

Redco Nylons, Polyurethanes and UHMW materials are used extensively to replace bronze and brass in sawmill and planermill applications. Click here for more information on bearings and bushing

- No Lubrication Necessary

- Reduced Initial Cost

- Improved Performance

- Reduce Wear on Shafts

Redco™ Hydraulic Wrap

Cover and protect hose, wire and cables against chaffing, rubbing, crushing, kinking, ultraviolet weathering and other environmental factors which can lead to premature hose failure, downtime and costly repairs. Click here for more information on hose wrap.

Redco™ Outriggers Pads

Lighter and longer lasting than plywood or steel, Redco™ UHMW Outrigger Pads stand up to harsh weather and extreme environments to protect you and your equipment from costly accidents. Click here for more information on outrigger pads.

- Lightweight, 1/7th The Weight Of Steel

- Withstands Loads Up To 3000 psi

- Retains Its Physical Properties To -80°c

- Will Not Corrode, Rot, Or Rust

- High Impact & Wear Resistance

- Can Withstand Over 1,000,000 Lbs Of Compressive Load

Redco™ 750 Hose Clamp Saddle

Traditional parts that are made out of Nylon tend to break or chip over time. Redco 750 hose clamps keep the hydraulic hoses in line with the boom on the processor while it slides back and forth along the boom.

Redco 750 is also molded to save on costly machining and for optimal tolerances.