Molding, Fabrication & Machining Services

Redwood Plastics and Rubber is your full service solution for plastic, rubber and composite components of the utmost quality.

Need Help Designing a Part or Choosing the Most Optimal Material?

We offer FREE onsite or virtual consulting

We’ve been problem solving since 1971 so you don’t have to.

Partner with experience you can trust.

CALL AN EXPERT 833 381 1195

3D Modeling -> Conversion to 3D CNC Programming -> Automating Milling, Turning and Routing

= Part Consistency & Quality each and every time

• Innovative Machining Techniques

• Reliable Quality Control Procedures

• CNC Machining & CNC Turning

• Quick Lead Times

• Short-run or High Volume Orders

• Local Manufacturer

CUT-TO-SIZE

We have a variety of tools and processes to cut rubber and plastic materials to size or into custom shapes. We have a variety of plastic cutting processes available including CNC machining and table saws, to cut plastic sheet, rod and tube.

DESIGN SUPPORT & TOOLING

A fundamental part of our organization is to support our customers with application and product design. We help with material recommendations and provide optimal manufacturing processes with cost-saving concepts. We can work with your existing design as well as assist in developing new custom parts.

PLASTIC & RUBBER FABRICATION & CNC MACHINING

Every branch is equipped with a complete machine shop for single run items or for large quantity runs. CNC Machinery allows us to manufacture in-house molds and cut precision parts. We can bend, form, cut, drill, or weld almost any plastic or rubber material to your specifications.

PLASTIC & RUBBER FLASHCUT CNC (KNIFE CUTTER)

Excellent cutting precision with high speed cutting and punching speeds for gaskets, rubber, plastics, conveyor belting materials, composite materials and laminated materials.

PLASTIC & RUBBER WELDING

There are many types of plastic materials that can be welded for repair or construction. Tanks, tank repairs, duct, drip trays and industrial piping systems to name just a few.

CUSTOM MOLDING

We represent manufacturers of various types of custom molding & extrusion. In partnership with our manufacturing divisions, Redwood Plastics and Rubber can mold your product to exact specifications with the latest design software and the most advanced equipment. We will work with you to ensure your product or application will be a success.

3D PRINTING

Custom 3D printing for components, molds or prototypes is available in a wide range of materials.

ON-SITE TECHNICAL EXPERTISE

Redwood Plastics and Rubber has a large outside sales force that can visit you on location and help you determine the most optimal material for your application.

On-site technical expertise and presentations are limited by location. Please contact us to schedule a meeting.

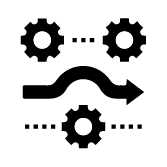

Unparelled Polyurethane Manufacturing Capabilities

We have the capability of casting urethane components in any colour and any durometer from 55A to 75D.

We produce TDI and MDI urethane parts including food grade, FDA compliant materials.

All our formulations are controlled by our Design and Engineering department, with our machines loading the formulations directly from our ERP software on a job by job basis.

Each polyurethane mold has a unique RFID tag that controls all the parameters of your job, from Part quantity, formulation, colour, durometer, and/or any proprietary additive, fire retardant or friction modifier.

Our polyurethane machines are capable of continuous casting at flow rates up to 75LB/min. Our casting ovens are 50’ long x 12’ wide x 12’ tall.

Part sizes can be as small as a few grams and we have no maximum size for some materials. The largest single part we have done to date is well over 2,500 LB. The continuous casting process we have will dispense as much material as is required to fill nearly any size mold.