At times in the plastic industry it seems like certain engineering plastics such as UHMW-PE and PTFE get all the attention as far as properties and applications. While those polymers certainly are worthy of attention, other plastics have outstanding characteristics, which should not be overlooked.

Redco™ Polyurethane is one of the most versatile and remarkable plastics available and can be used in a wide array of applications that perhaps no other material can compete with. The following is a primer on the unique characteristics, grades and possible applications for Redco™ polyurethane.

Why Polyurethane ?

Versatility: Redco™ Polyurethane comes in a wide range of hardness’s – from bouncy ball soft to bowling ball hard. This opens up a breadth of potential application – from shock pads and deadplate on the “soft” end, to heavy-duty bearings on the “hard” end that will outwear traditional brass and bronze.

Memory: Perhaps the most unique properties of Redco™ polyurethane is its memory. It can absorb impact and dent, only to rebound and regain its original shape. Other plastics do not have this ability. This makes urethane the ideal material for shock absorption and deadplating.

Other properties:

- Unlimited molded shapes

- High-load bearing

- Oil and solvent resistant

- Resistant to Aging

- Heat resistant (250 f)

- Cold resistant (-60 c)

- Exceptional impact strength

- UV stabilized

What is the “A” and “D” scale?

Urethanes are classified to a hardness scale called the “Durometer” rating. This is an often confusing scale to those unaware of polyurethane classification. For example, Redco™ produces polyurethanes in grades of 70A and 75D – don’t be fooled – those are vastly different materials. A classification of “A” denotes a soft urethane (on same scale as rubber) and a Redco™ 70A polyurethane would be commonly used as shock pads. A Redco™ 75D polyurethane ,on the other hand, is bearing-grade material with high impact strength designed to replace metals in applications. “D” refers to the plastic scale, which in this case denotes a hard urethane.

Sample Grades:

To illustrate the wide variety of Redco™ polyurethane available we’ve provided a few examples below.

Redco™ Deadplate was designed for maximum energy absorption. It is commonly used in sawmills as a bumper for  incoming logs that impact a part of the machinery. Deadplate has a rating of 52A and would feel like a “tough” rubber pad to your touch.

incoming logs that impact a part of the machinery. Deadplate has a rating of 52A and would feel like a “tough” rubber pad to your touch.

Redco™ 430 is an abrasion resistant material with outstanding impingementresistance. As a mid-grade material in the range of urethanes, it can be classified by hardness ratings of 90A or 43D. This grade has a variety of uses from shock pads to seals, couplings, valve gates and wear slides among many others.

Redco™ 430 is an abrasion resistant material with outstanding impingementresistance. As a mid-grade material in the range of urethanes, it can be classified by hardness ratings of 90A or 43D. This grade has a variety of uses from shock pads to seals, couplings, valve gates and wear slides among many others.

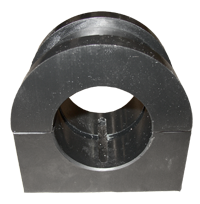

Redco™ 750 SXL is used in sliding, low temperature, and gritty environments. It is an excellent bearing material and has great self-lubricating properties. Its durometer rating is 75D and is used in bushings, bearings, diffusers and retainers.

Redco™ urethanes are an excellent material for an impressive breadth of applications. If you have questions regarding your application please contact us today.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684