In the world of mechanical/industrial grade plastics PET-P commonly known simply as “PET” is the underappreciated soldier. PET performs every day in harsh environments: farming machinery, food processing, and medical industries in particular. It’s constantly dirtied, steamed, soaked and coated with all sorts of substances every day – but it doesn’t get any respect!

PET (polyethylene terephthalate) is a crystalline, high-molecular weight plastic that is notable for its balanced properties. It is most similar to acetal and is an excellent substitute for it in many applications. In particular vs. acetal, PET can handle a higher operating temperature – 230 degrees Fahrenheit constant – and is not affected by chlorine cleaners or wash downs (unlike acetal). In addtion, PET is very dimensionally stable – a significant advantage it holds over more popular plastics such as UHMW and nylon.

Another important note is that PET is FDA approved for direct food contact. It serves as a “bridge” between plastics with a lower temperature threshold such as UHMW and acetal and more expensive heat-tolerant plastics such as your virgin and filled PTFEs.

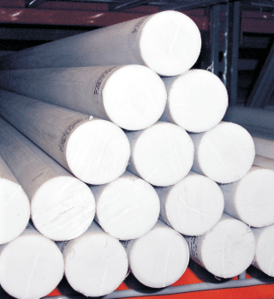

Redwood Plastics can quote PET parts complete or material alone; however, none of our branches stock PET so please be very specific about your requirements as minimums may apply.