Bushings are used in all types of manufacturing industries and food processing is no exception. Metal bearings such as roller bearings and bronze bearings are widely used but, as in other industries, plastic bushings tend to perform significantly better than metal, permitting less maintenance, increased production, and reduced downtime. Yes, the upfront cost of a plastic bushing is usually more than a metal one. But ask yourself how quickly you would expect a bushing that is a few dollars more to pay itself off with more production and less maintenance work? Plastic bushings are suitable especially when you need:

- Increased bearing life

- Less or no greasing

- Self-lubrication properties

- Better wear and lower coefficient of friction than metals

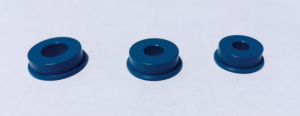

There are several food-safe (FDA) compliant plastics for this application. One of the very best is Rulon 641: a white, food-grade bearing material with phenomenal load and wear characteristics. Rulon 641 can handle a pressure velocity (PV) value up to 10,000 and is suitable for pairing with mild, 303 or 316 steel. Another bushing material that performs very well in food processing applications is Redco acetal. Acetal is a very hard plastic, but also very machinable to tight tolerances and the homopolymer (white) version of the product is FDA compliant. As is the new blue acetal now showing up more in applications, as the blue has a color different than most foods and that visibility is desirable to many customers in the food processing industry.

Several other plastics can be used as bearings in certain applications: white-natural UHMW polyethylene and certain food-safe grades of nylon or polyurethane as well. However, acetal and the Rulons will often be choices where you cannot go wrong. The first step in us assisting you with your food-safe bushing is to fill out our bushing design form. You can then upload it to our RFQ form and email us here.